SCREENS

In addition to raw mesh production we provide design and manufacture services for forming & framing screens for individual process requirements.

Production includes DSM run-down screens, bow screens, fabricated filter elements, coanda screens, dewatering solutions, centrifuge baskets

and water intake technology.

Industrial Screens and Filters

Screens - Industrial Screens and Filters

Wedge Wire is a long established accurate filter screen solution for liquid/solid and gas/solid separation. The screens are known for their great strength and long service life. The screens are produced by resistance welding at 90 degrees to support rods and the result gives a smooth, straight, two point contact flow path which is not easily clogged by debris.

Various wire profiles are available and slot size can be chosen to suit any application. Flat, curved and cylindrical screens are supplied for manufactures and operators to use for filtration, dewatering etc. We also supply engineered equipment with wedge wire elements which can be one of our standard designs or tailor made for specific applications.

Our industrial screen and Filter range also includes perforated sheet and mesh. The section of this web site entitled Filter Elements is dedicated to products manufactured from woven wire mesh and perforated metal.

OEM Wedge Wire Screens

-

Heavy duty wedge wire basket

Button

View more

Filtration

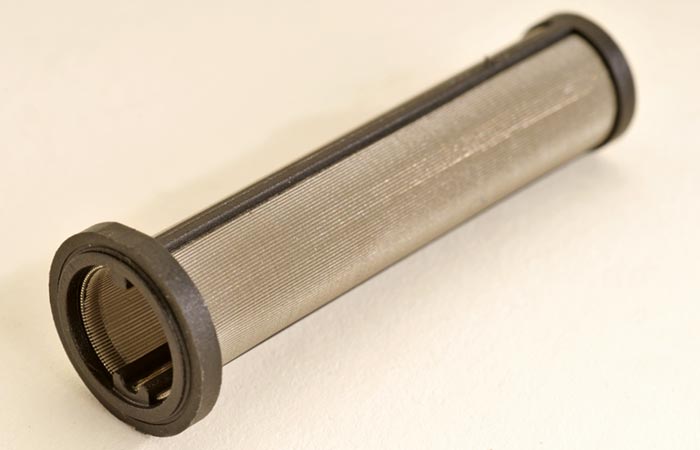

Cylindrical, Flat, and Curved Wedge Wire Screens

The tapered wire and continuous slot means that there are only two contact points for particles and this minimizes the risk of clogging.

Slot sizes can be chosen from 30 microns to 25 mm. Available in stainless steel and exotic alloys including Super Duplex UNS S32750/60 and Uranus 52N. Screens can be supplied with custom details such as threaded ends, handles, blank ends, brackets and flanges for applications such as filter baskets, backwash elements and intake screens.

-

Various wedge wire filter elements

Button

View more

Robust & Easy To Clean

Baskets with Inner Scrapers

Wedge wire is ideal for self-cleaning filters as it does not clog in the way perforated/woven mesh can be susceptible to the build-up of solids.

Wedge wire is also easily back-washed and can be designed with radial or longitudinal support rods as well as being suitable for flow in-to-out or out-to-in.

-

Vessel internal header with central outlet

Button

View more

Media Retention

Laterals

These assemblies consist of a series of wedge wire screen lateral tubes connected to either a central header pipe or a hub. Laterals are installed in carbon towers, ion exchangers, sand and clay filters etc. to retain media in the process vessel.

They can be supplied complete with threaded fittings, couplings or flanges. Slot sizes available are from 0.05 mm and up in increments of 0.01 mm. Diameters are available from 20mm upwards.

Media Retention

Nozzles

Used in pressure and gravity sand filters as well as collectors and demineralizers, the effectiveness of nozzles is dependent on close limit tolerance and stringently controlled production quality.

Standard diameter is 50mm, typical slot opening ranges from 0.2 mm to 0.5 mm with high open area.

Filter Elements

Aerospace

Guards, Flat Mesh & Pleated Screens

For cooling systems, air intake, landing gear, breaking and steering, our EN9100 certified production serves helicopters as well as commercial and military aircraft.

Rolls of woven copper wire are used for lightning strike protection in composites.

Automotive

Our range of ISO/TS 16949 production includes fuel and gas filters as well as filters for pumps and hydraulic circuits & cooling systems. Our knitted wire products include air/oil separators, gaskets, both with and without flexible graphite, for use in exhaust manifold mounting seals and system joints.

Related products are anti-vibration, sound attenuation & heat shields. Together with exhaust decoupling rings and mesh bellows sleeves, break components, airbag filters and catalytic converter seals. Our services include prototyping batch & high volume production.

Capital Goods & Screen Re-Meshing

Flat discs, screens and elements

We supply metallic mesh filter elements with plastic/nylon overlay framing in low, medium and high volume production.

We also offer a re-meshing service for process industry screens and removal/replacement/refurbishment of mesh printer ink dispensing nozzles.

Electro mechanical

Faraday Cages

Used to block out external static electric fields we supply small and medium batch production tailor made copper Faraday cages complete with brackets and cable connection points.

They also minimize influence of high-frequency electromagnetic waves such as radio waves and fluorescent lighting.

Power and Energy

Flanged, Inline Basket and Pleated Filters

Elements can be suppled for a variety of filter types including Y type, T type, backflush, temporary, multi basket and coalescers.

Baskets and elements can be designed for high contamination levels or for low pressure loss in high velocity applications such as meter protection and pump suction applications with relatively low contamination levels. Vertical pleated screens offer much lower clean pressure drops than conventional baskets.

Conical Strainers

Perforated Large and Small with Fine Mesh Option

Also known as ‘witches hat’ strainers and ‘temporary strainers’ they comprise either conical shaped perforated sheet only or with additional layers of woven wire cloth weld to the perf.

The perforated sheet material gives structure for maximum rigidity and the multilayer mesh forms the fine filtration, maximizing flow area and reducing resistance thus ensuring safe operation of equipment downstream.

Inline Filters

Disc Type, Threaded and Insert

Filter discs or tubular inserts are supplied in housings so that they can be integrated into the customer’s installation.

The elements are designed for long in-service life for specific applications to withstand full system pressure. They enable easy replacement of the filter.

Oil & Gas

Cylindrical Baskets, Pleated Baskets, Tubes and Flat Screens

Perforated and mesh baskets complete with flanges, blanked ends, handles and any other brackets can be provided to your designs. We also supply pleated baskets in any material including exotic alloys such as Super Duplex and Hastelloy.

In addition to production our engineering department is able to use customer process conditions to engineer solutions sizing elements to suit all applications.

Petrochemical

Flat Discs, Screens and Elements

We offer a range of disc type filters to fit standard pipe sizes.

These filters are be designed to customer specifications and can be flat discs or pleated mesh giving extra filtration area and offering maximum efficiency.

Water Intake Technology Water Treatment

Wedge Wire Coanda Screens

Coanda screens are used in dam and river systems to protect fish from hydroelectric turbines and pumps - addressing the problem of the intake of debris and the build-up of silt.

Passive Intake Screens

High capacity passive intake screens provide constant, uninterrupted water withdrawal from shallow rivers, to lakes and oceans. With integral duel flow modifier almost totally uniform, low flow is created over the entire screen surface. This significantly reduces impingement whilst protecting aquatic life.

Our passive intake screens are designed to provide a low and evenly distributed slot velocity, typically less than 0.15 m/s which is the maximum acceptable velocity to allow juvenile fish to turn around and swim away in compliance with the Eel Regulation (England and Wales) 2009. The screens can be suppled complete with backwash system for operation in areas of high concentration of debris.

DSM Rundown Screens & Bow Screens

Sieve Bends

120 Degree DSM Screens

Sieve Bends are extremely effective for solid separation and/or dewatering. They are used extensively in a multitude of industries.

The unique design Wedge-Wire facilitates static, non-clogging operation because only particles about half the aperture width pass through the screen. This prevents blinding by material near to aperture size in most applications. Hydraulic Capacity from 36 to 306 m3/h, Slot opening from 0,3 to 1,5mm.

Advantages

- Design specially optimized for individual industries including starch

- Tilted wire on the screen

- Acceleration ramp before effluent reaches the screen

- Better separation efficiency due to designs based on speed of fluid flow on the grids

- Increased duration between cleaning phases

- Tangential flow

- Standardized box and grid sizes provide flexibility

- Weir tank sized to reduce turbulence for optimum flow distribution across the screen

- Weir tank front cover prevents dripping

- Back of the equipment covered

Knitted Wire Mesh & Associated Products

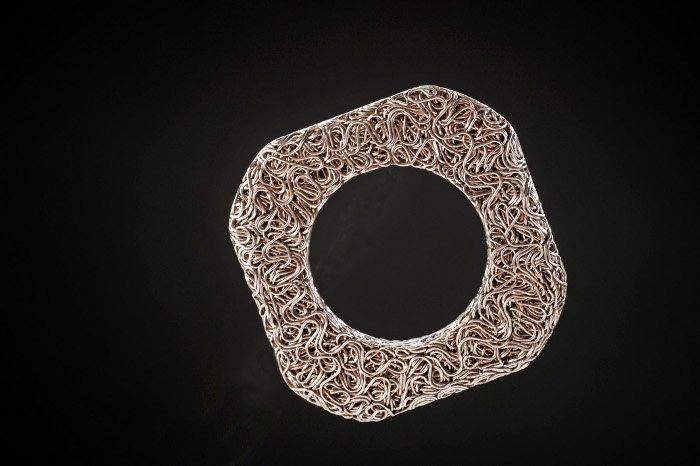

Knitted Wire Coalessor Element

These elements are designed to locate inside horizontal vessels. Given operating process conditions, the elements can be sized according to process calculations and manufactured in a variety of different materials including stainless steel, galvanized steel and polypropylene.

The image above is an element to suit a 2300mm ID vessel and it has a thickness of 300mm.

The grade 304L knitmesh core is chevron corrugated. The circular elements have been designed in two separate halves to allow them to be passed through a manway into the vessel during installation.

Wound Compression Pad

Using wire knitting technology, compression pads are manufactured for automotive applications including anti-vibration, sound attenuation & heat shielding.

They are highly effective absorbers of heat, noise and vibration energy.

Rings of similar construction type are also available and are used for exhaust decoupling joints, mesh bellows sleeves, decoupling joints.

They absorb vibration, take up thermal expansion and reduce noise.

Polypropylene Demister Element

Also known as a coalessor element, the image above shows an element to suit a 1860 mm ID vessel.

The element separates liquid from gas with no product lost from the liquid phase.

A wide range of gas velocities can be accommodated with maximum efficiency.

It also acts as a fine filter, down to as low as 2 microns.

Pressure loss is minimal.

Knitted Wire Filter Panel

Metal washable panel air filters are manufactured in galvanized or stainless steel with a knitted wire core for coarse grade filtration to G2 to EN779:2012.

These panel air filters are used for primary filtration, removing large particulates in HVAC systems, air handling units and workshop applications.

They are also fitted as integral components in air cooling systems for data centres.

Food & Beverage, Sugar, Starch, Brewing, Malting & Distilling

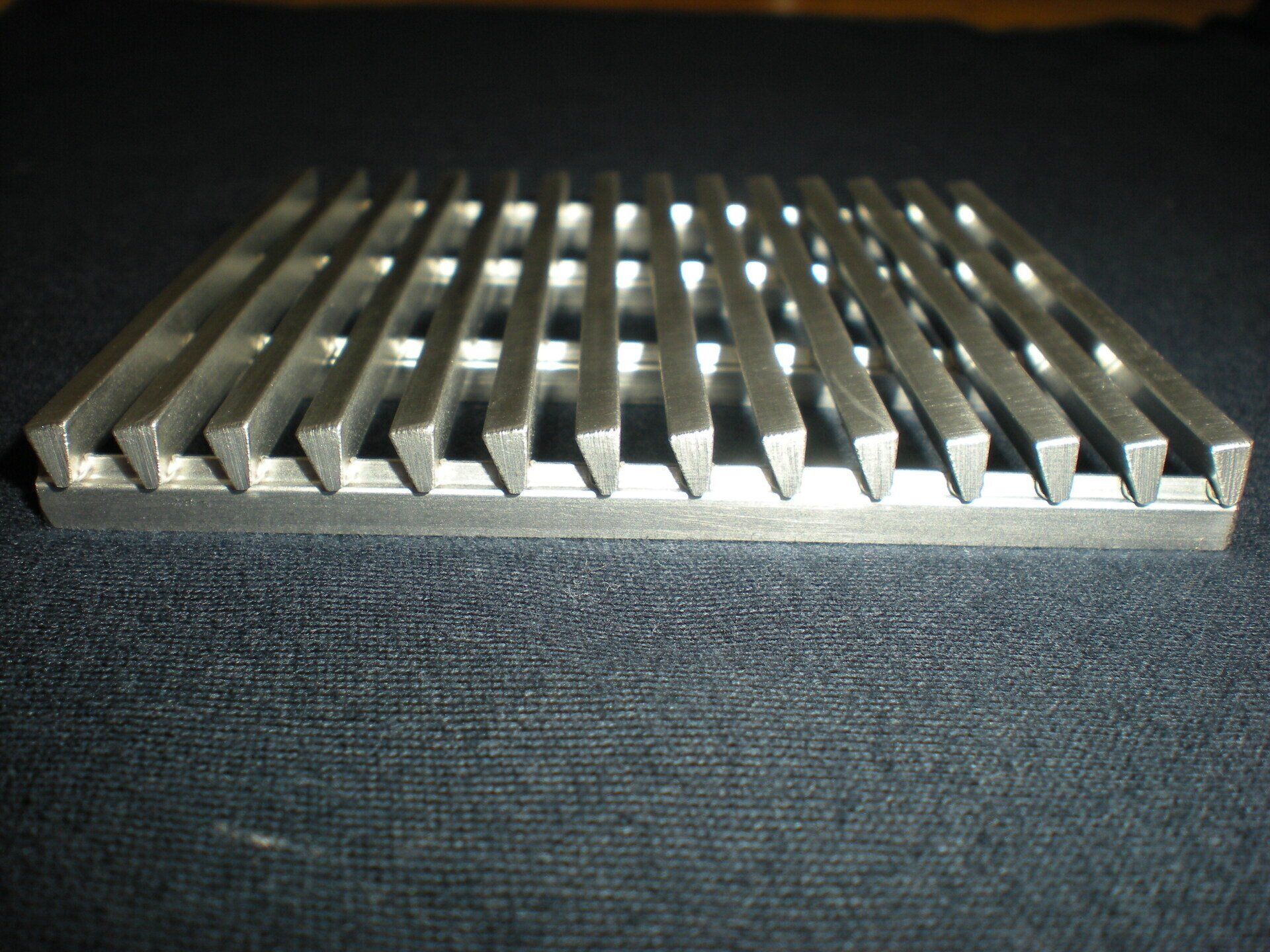

Support Screen

These screens can be designed as self-supporting structures to withstand any flow rate differential pressure as well as load of operators walking on them for access and maintenance.

Used for many applications including mash tun flooring they can be supplied in segment sizes that are small enough to be fitted into vessels through a manway access hatch.

They have larger open area than with wire mesh/perforated plate designs.

Centrifuge Basket

Continuous centrifuge wedge wire baskets are very robust with high precision slots and large open areas.

They are used in the starch and sugar industries to give longer working life due to their abrasion resistance. They are also less susceptible to damage during start up compared with thin perforated/etched sheet.

Long screen slots produce less crystal degradation thus ensuring more finished product output per ton than any other centrifugal screen. The self-supporting structure of the basket is engineered to withstand the high stresses and load conditions of the process.

Copyright © Intamesh - 2018. All rights reserved.